Flexibility of Steel

Flexible and persistent work.

Steel materials that stretch and change shape according to the mold. It also has a toughness that is not easily broken even when subjected to force. Our approach to work is exactly the same. In order to respond to the needs of complex shapes and small lots, we brainstorm, overcome difficulties, and always strive to make proposals that exceed expectations.

Product development that responds to customer orders.

"We can't make a steel bar in this shape" or "Can't we secure this much strength?" We receive various inquiries from our customers. In order to realize such requests, the management department responsible for mold design and quality control conducts research and prototyping on a daily basis. The results obtained are shared with other departments at monthly meetings, and we strive to improve our overall technology and spirit.

Implementing TQC activities that constantly improve and improve.

Based on the commitment to quality and responsibility to customers, we are continuously working on TQC activities (Total Quality Control) to improve customer satisfaction and management efficiency. We repeat training based on 7-8 themes such as improvement of manufacturing technology, review of process design, and streamlining of work efficiency, and also hold presentation sessions by group units. A corporate culture where opinions can be freely exchanged regardless of department or career leads to even higher quality.

Obtained ISO9001 certification for quality assurance.

"We have been evaluated for our efforts to improve customer satisfaction and management efficiency, and obtained ISO9001 certification for quality assurance in 2003. The Chubu factory, completed thereafter, also obtained the same certification. Without being complacent, we continue to work on improving the quality of our products and manufacturing processes every day, with the motto of responding to customer needs and gaining trust and satisfaction.

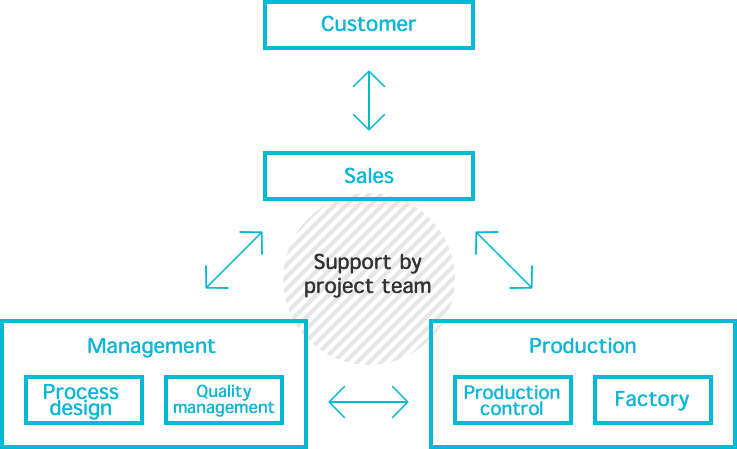

Build a team structure in which each department cooperates organically. We establish a team structure where each department collaborates organically. At Sanyo Metal Industry, we organize small teams consisting of members from each department for each customer. By working in small groups, communication becomes smoother, and we can respond to our customers' needs in a more detailed manner. Additionally, individual achievements are more visible, and competition between teams leads to increased motivation, resulting in high-quality products and attentive services.

When a customer consultation is received, the sales department first conveys it to the management department. The management department is responsible for engineering and quality control. They further collaborate with the production department, which handles production management and progress, to discuss how to shape the customer's needs and what processes are optimal. Then, the production department presents an estimate to the sales department, and if the customer is satisfied, manufacturing in the factory begins. Feedback on the manufacturing process is constantly provided to the sales department.

Product information